ABOUT US

-

About EIE

Epunion International Enterprise (EIE) specialises in developing innovative surface finishing chemical solutions. Our Head Office and R&D Centre is located within the Thailand Eastern Economic Corridor (EEC) in the Chonburi province. We also have a sales office located in heart of Shanghai. Our team of engineers are always exploring new concepts and trends to develop truly unique chemical processes.

We prioritize the importance of our end-users, and that is why we also have a strong distribution and technical support network that spans across a muliple of countries within the Asia region.Our Slogan: Finishing First

This phrase holds two messages. Firstly, it describes the priority of surface finishing to us, hence “Finishing First” Secondly, it reminds us to stay competitive by "Finishing First".Origin of epunion

The brand epunion was created in 1983 by Mr. Jyh-Rong Liang as a Portmanteau word short for "Electroplating Union".

The logo is also designed as an ambigram. Which means when flipped upside down, it reads: uoiun-da, which in Chinese reads: 遠大 (Far & Big). The use of this ambigram is to remind us not to lose sight of aiming far and dreaming big.

Throughout the years, epunion products were produced and marketed by our local partner in Thailand, but as the brand recognition started to grow, we knew we had to start a new company to manage the future growth of this brand.

In 2016 we founded Epunion International Enterprise (EIE) to be more focused on developing competitive and environmentally-friendly products for the surface finishing industry.

-

Our Mission

Our mission is to have a positive impact on the markets with our finishing touch.

To do so, there are many ways to achieve this. However, we hope to focus on environmentally-friendly processes that can offer an inherent advantage over traditional products. This is what we call the ECO-MEKKI development philosophy. -

Our R&D Philosophy

ECOMEKKI is our R&D philosophy. ECO is an acronym for Environmental Chemistry Optimization. As chemical makers, it is responsibility to develop environmentally-friendly solutions. Not only because we want to have a positive impact on our industry, but also, we believe in working attracting customers with a high corporate social responsibility.

The word MEKKI, comes from “electroplating” in Japanese. It is a nod to our electroplating origin. As we explore other areas of surface finishing, we should not lose focus on our core business..

During our product development cycle, we need to evaluate the purpose behind developing any product by evaluating these 6 advantages:- Reduction of overall energy consumption

- Reduction of overall water consumption and effluents

- Reduction of total cost for the user

- Reduction of chemical consumption

- Superior performance

- Future regulation compliant

The more points we can fulfill, the higher on the ECOMEKKI list it is. By implementing this thought process, we can stay true to our Mission.

PRODUCTS

-

Our product range covers a very broad spectrum of the surface finishing industries and is constantly being updated and upgraded. Our products can be grouped into the following categories:

- Industrial & General Cleaners

- Functional Plating Additives

- Decorative Plating Additives

- Conversion Coatings

- Top Coats and Sealers

- Chemical Strippers

- Colors, Dyes, and Pigments

For a more detailed look into our product range, we recommend referring to our Product Catalog or just contact us directly. Please find an introduction to some of our more forward-thinking push products below:

PUSH PRODUCTS

-

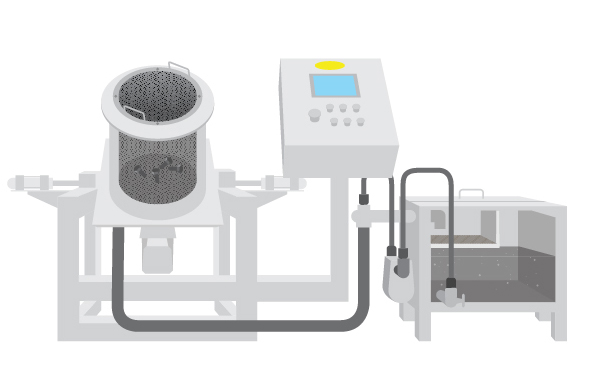

Nanomono Top Coat Series

Nanomono Top Coat Series

A series of nano-ceramic and electrophoretic top coats that can achieve an unparalleled appearance, uniformity, and corrosion resistance. When used with our Spinano machine or with our Closed-loop Ultrafiltration unit, the chemical consumption of this process can be controlled to a very low volume. More importantly it also produces very little waste and contains no SoHC making it a very environmentally friendly process.

-

Trilux Cobalt - Free Trivalent

PassivationTrilux Cobalt - Free Trivalent Passivation

The demand for a cobalt-free trivalent chrome passivation is on the rise for two reasons: The cost of cobalt is unstable, cobalt is on the watch list of substances of hazardous concern for REACH in Europe. Our Trilux µ83 is truly a cobalt-free system without any compromise. It is a single component product that many customers have chosen to adopt not because it is cobalt-free but because it is just a very solid product.

-

Chrome Free Passivation

Chrome Free Passivation

Arguably, the future of passivation will become Chrome-free. In most cases, the applicator will have to give up some practicality or performance when changing to a chrome-free system. However, we have found several ways to adapt to a chrome-free system, without compromising product performance. For example, it is very easy to combine our chrome-free passivation with Nanomono top-coats to produce a finish that has a very clean environmental footprint, but also, one that will match, if not out-perform, the traditional solutions. For more information about our chrome-free systems, please contact us directly.

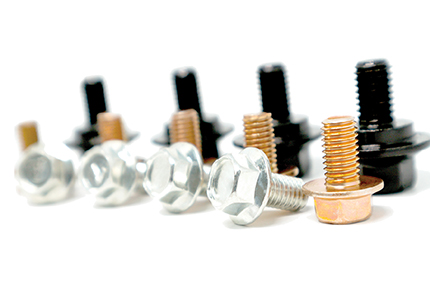

Spinano 400DS

Spinano 400DS

The Spinano machine when used in conjuncture with our nanomono sealants is able to achieve an unparalleled finsih.

Both the appearance and corrosion resistance will be upgraded after this process.

lt is also possible to adjust the coefficient of friction to suit the requirements of the user.

The machine has a Programmable Logic Controller that allows the adjustment of many variables such as the rotation speed, cycle time, chemical dose rate, and tilt angle.

Typically 1kg of sealant can be used to coat 500kg of fasteners (size M8) with a thickness of around 1 to 3 microns.

PRODUCT CATALOG

-

Conversion Coatings

Conversion Coatings

Application Product Features Non-Chrome

Conversion

Coatingsepcoat 5300 Non-chrome conversion coating for Al and Al alloy No need water rinse after coating. ephos Zn-100 Zinc phosphate Suitable for iron and steel substrates High corrosion resistance. ephos Zn 4990 Suitable for iron and steel substrates Produces micro-crystalline layers Low sludge. Black Oxide epneo 790 Suitable for barrel and rack application Color shade is adjustable from light brown to black. epneo 5090 Powder Black oxide application for steel and iron with uniform black finish. epneo 5100 Liquid solution Used in treating steel and iron parts by immersion at room temperature.

-

Phosphating

Phosphating

Application Product Features Zinc Phosphate ephos Zn-100 Thin Film Zinc Phosphate for paint pretreatment. ephos Zn 4990 Thick Film Zinc Phosphate for anti wear functions. Manganese Phosphate ephos M5040 Functional coating for wear resistance.

-

Non-Cyanide Alkaline Zinc Series

Non-Cyanide Alkaline Zinc Series

Application Product Features Rack & Barrel CK 700 For both barrel and rack plating, a brilliant zinc deposit that is easy to use. HT45 High temperature Alkaline zinc, for tropical nations without chillers. Ideal operation temp at 40 to 45 celcius.

-

Acid Zinc Series

Acid Zinc Series

Application Product Features Water based additive ecozin 540 Suited for both barrel and rack plating excellent brightness and ductility. Compatible with Ammonia, potassium, or mixed type baths. Potassium Type Bfit Boric-acid free potassium type acid zinc with near Neutral pH.

-

Zinc Alloy Series

Zinc Alloy Series

Application Product Features Zinc Nickel ZiNYX Barrel and Rack process with uniform alloy deposition of 12 - 17 % nickel and good low current density performance. Zinc Iron Zefiro Barrel and Rack process, good corrosion protection and nickel free.

-

Nickel Plating

Nickel Plating

Application Product Features Semi Bright Nickel Dupnex Ni Semi-bright deposits over a wide current density range, and excellent leveling. High Sulfur Nickel HS 303 Good adhesion on semi-bright nickel deposits, ideal for increasing corrosion resistance. Bright Nickel Nitech Very high leveling and brightness Suitable for plating on steel, brass, zinc based die casting and

copper plated components.BNP Very high leveling and brightness, maximum ductility throwing power and chrome ability

Suitable for both rack and barrel plating on steel, brass, zinc based die casting and copper

plated components.Micro porous Nickel Nitech MP Micro porous Nickel with adjustable pore count.

-

Copper Plating Series

Copper Plating Series

Application Product Features Alkaline Cyanide CNC 401 Excellent brightness, levelling and covering power. Pyro Copper PY-61 Excellent adhesion for copper plating. Acid Copper Cupalon AR 208 Ultra brightness all over Excellent leveling at high & even medium current density, Dye-based additive. Cupalon 205 Ultra brightness all over Excellent leveling at high & even medium current density Dye-Free additive. Hard Acid Copper Cupalon AR 209 Ideal for printing shafts and similar applications.

-

Chrome Plating Series

Chrome Plating Series

Application Product Features Hexavalent Chrome Pltating epcrom 800 Decorative chromium process. Trivalent Chrome

PlatingUltima chrome

900 WTDecorative trivalent white chromium Sulfate-based trivalent chromium Bright and white chrome finish Plating speed of 0.05 to 0.1 microns per minute. Ultima chrome

910 DCDecorative dark chromium Fashionable and dark chrome finish Sulfate-based trivalent chromium High plating speeds achievable Uniform and consistent covering power.

-

Zinc Passivation Series

Zinc PassivationSeries

Application Product Features Trivalent Blue Chromate Trilux µ7X Series Characteristic blue finish for Zinc plating. Trivalent Iridescent Chromate Trilux µ8X Series Excellent corrosion resistance without topcoat. Cobalt-free option available. Black Chromate Trilux 391 Series Black Passivation for Acid and Alkaline Zinc plating. Chrome Free Passivation Titan 90 Chrome free passivation to be used with Nanomono top coats to achieve industry standard corrosion resistance properties. -

Nanomono Series

NanomonoSeries

Application Product Features Zinc Plating Sealant Trilux 100S Suitable for trivalent blue and yellow passivation, improves overall appearance and increases salt spray performance. Black Sealant nanomono BS 342 Solvent type topcoat, with excellent salt spray performance. Ideal for off-line application. nanomono BS 347 Waterborne solution, minimizing waste water and pollutants. Suitable for on-line & off-line applications. Clear Top Coat nanomono CWS 301 High Solid content Waterborne solution that vastly increases corrosion-resistance. nanomono CW 153P Waterborne solution that vastly increases corrosion-resistance. nanomono CW122 NEW Waterborne solution that vastly increases corrosion-resistance.

-

Anodizing Series

AnodizingSeries

Application Product Features Alkaline Etching epick 50 Scale inhibitor additive for Al etching process Increases the tolerance of Al content. Polishing epclen AL Series Nitric free Chemical polishing for aluminum. Desmutting epclen AD3 Series Aluminum desmutting process. Anodye Series Anodye Series A selection of 40+ colors. Water soluable organic based dyestuff with high fastness properties. Cold Seal eploxer 2430 Liquid solution, Nickel Acetate based cold seal. Hot Seal eploxer HNi Powder Nickel Acetate based hot seal.

-

Industrial Cleaners

Industrial Cleaners

Application Product Features Alk Degreasing epclean 20 series Powder based Low Alkaline degreaser for Light metals. epclen 5X Powder based high alkaline cleaner that contains caustic soda. epclen 6X Liquid based high alkaline cleaner that contains Potassium Hydroxide. epclen YC Powder based low cost degreaser that is caustic free. Electrocleaner epclen TL Series Electrocleaner suitable for Anodic and Cathodic cleaning. Surfactant Surfin-52 Recyclable emulsifying surfactant for soak and ultrasonic applications. Surfin-DM1 Recyclable demulsifying surfactant for soak and ultrasonic applications.

-

Functional Plating

Functional Plating

Application Product Features Electroless Nickel EN 8728 High Phosphorus content for maximum corrosion resistance. EN 6756 Medium phosphorus content with great appearance. SZ 500 Zincate pretreatment for Aluminum parts. Tin Plating Additives Stannyx Asn High Phosphorus content for maximum corrosion resistance. Stannyx MT 430 Matt Acid Tin additive. Stannyx 400 High Speed Tin additive. Stannous Sulphate High quality Stannous sulphate for Tin Plating.

-

Plating on Plastics

Plating on Plastics

Application Product Features Pretreatment POPILON 202 Chromic etch wetting agent. POPILON 203 Neutraliser after Hexavalent chrome etch. POPILON 3012 Palladium Activator. POPILON 3021 Accelerator after Palladium process. POPILON 403 Electroless Nickel after Accelerator.

-

Water Treatment

Water Treatment

Application Product Features Spray Booth Paint Killer epfall Series Easy to use three compenent system that effectively removes paints from the spray booth water.

-

Chemicals Strippers

Chemicals Strippers

Application Product Features Metal Stripper NCS Series Nickel Strippers. TS Series Tin Strippers. Paint Stripper epzeno Series Paint Stripper.

SERVICES

-

Industries with our Finishing touch

Industries with our Finishing touch

Our branded products have been used to serve the following industries below Our branded products have been used to serve the following industries below -

Automotive Industry

Automotive Industry

Cleaning , Zinc,

Decorative plating, POP

Paint Pretreatment and

Aluminum Passivation Cleaning , Zinc,

Decorative plating, POP

Paint Pretreatment and

Aluminum Passivation

-

Motorcycle Industry

Motorcycle Industry

Paint pretreatment and Anodizing

Paint pretreatment and Anodizing

-

Medical Industry

Medical Industry

Conversion coatings, Anodizing and

Electroplating

Conversion coatings, Anodizing and

Electroplating

-

-

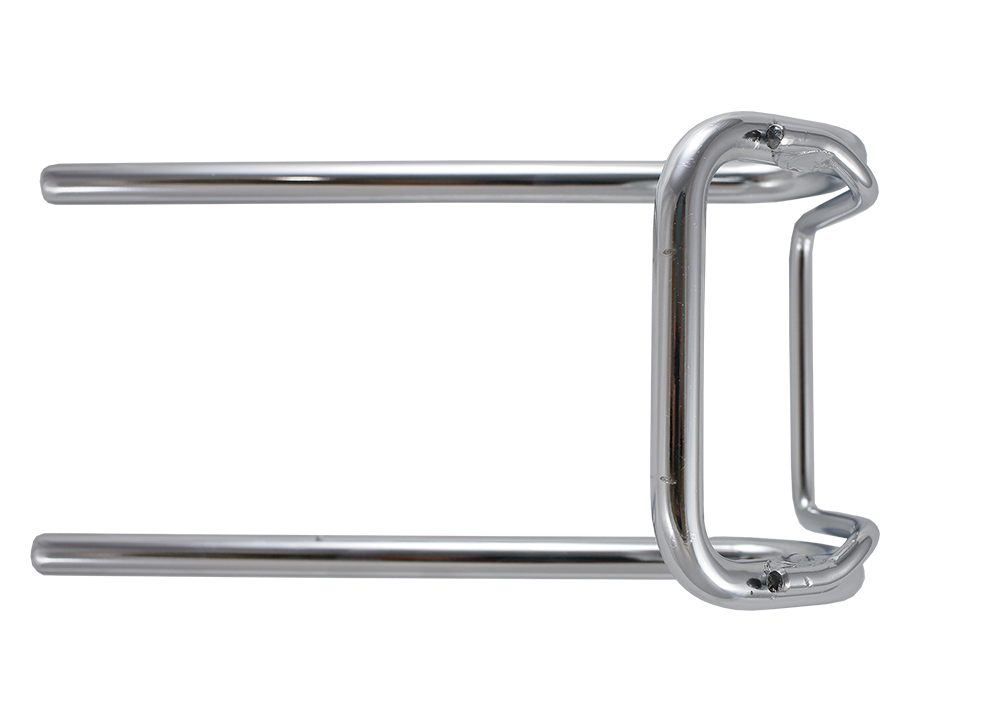

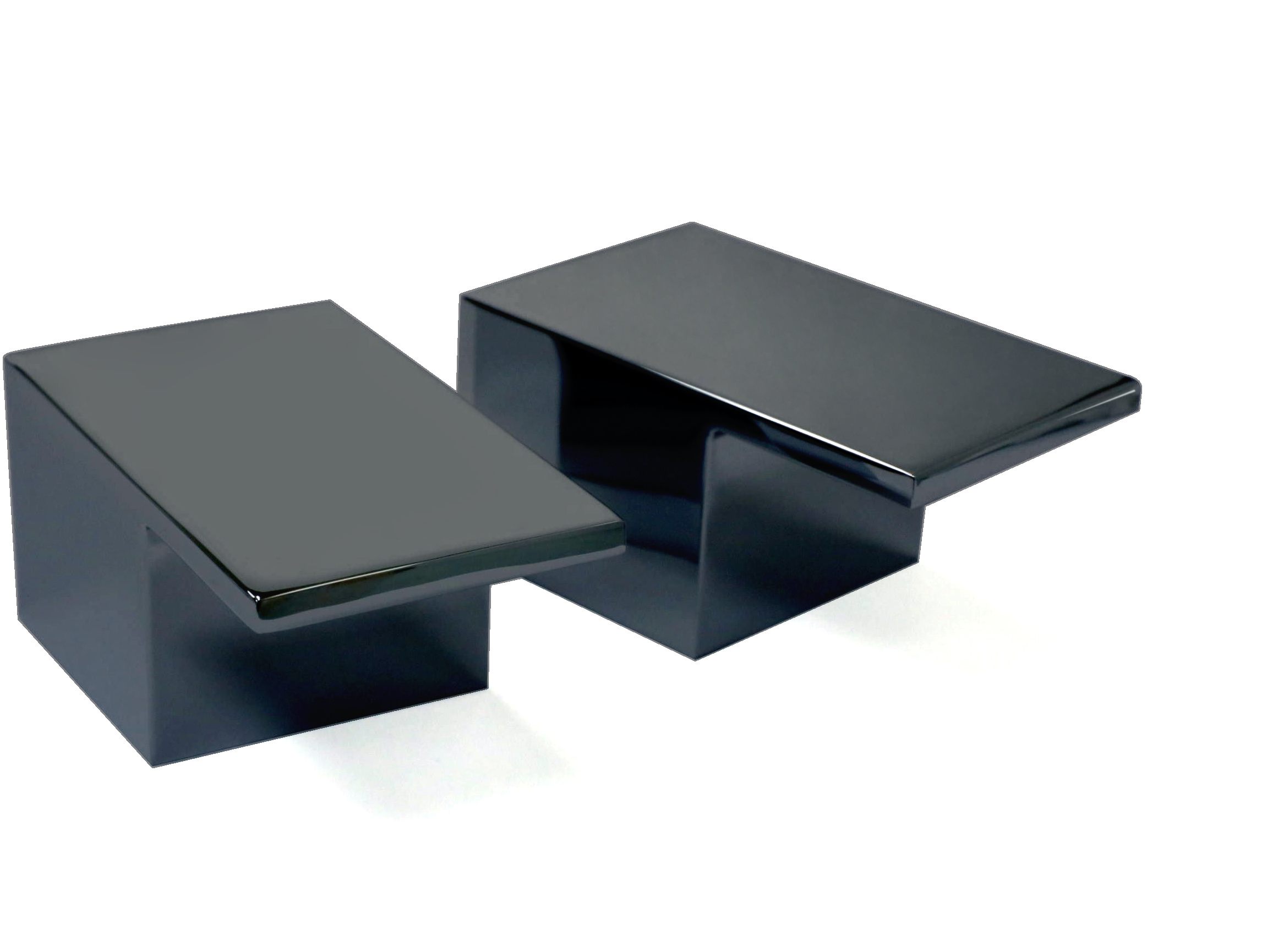

Furniture Industry

Furniture Industry

Electroplating, Chemical polishing

Electroplating, Chemical polishing

-

Electric Vehicle Industry

Electric Vehicle Industry

Battery Nickel plating, Aluminum

Passivation

Battery Nickel plating, Aluminum

Passivation

-

Aerospace Industry

Aerospace Industry

Conversion coating and Anodizing

Conversion coating and Anodizing

-

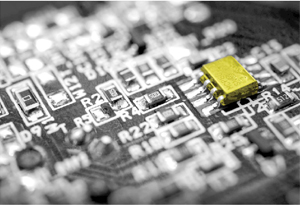

Electronics Industry

Electronics Industry

Silver plating , Chemical polishing

and Electroplating

Silver plating , Chemical polishing

and Electroplating

-

Construction Industry

Construction Industry

Zinc Plating, Zinc Phosphate Zinc Plating, Zinc Phosphate

-

Future Industries to

Cross intoFuture Industries to Cross into

- Food Industry

- Agriculture Industry

- Power industry

- Waste water and Water Treatment

- Industry

- Wood industry

contact

Our Distribution Network

ASEAN Network

With Partners and Distributors around the ASEAN region, we have thefollowing presence in these countries:

Thailand, Taiwan, China, Japan, South Korea, Indonesia, Malaysia,

Vietnam, Bangladesh, India, and The Philippines.

For products and services inquiries please contact us at

inquiries@epunion.com

We are always looking to expand. Please email us whether you may

want to work with us to expand your product portfolio in your market.

THAILAND

Epunion international enterprise .Co., Ltd. 78/9 Moo 5, Takam, Bangpakong, Chachoengsao, 24130 Thailand.Tel +66 (0) 38 554 324 Fax +66 (0) 38 554 325.

CHINA

Epunion (Shanghai) Enterprise Co., Ltd. 7/F Building 1, 818 Road Shenchang, Shanghai, PRC 200335 China.Tel +86 138 1781 3488.

contact

Our Distribution Network

ASEAN Network

With Partners and Distributors around the ASEAN region, we have thefollowing presence in these countries:

Thailand, Taiwan, China, Japan, South Korea, Indonesia, Malaysia,

Vietnam, Bangladesh, India, and The Philippines.

For products and services inquiries please contact us at

inquiries@epunion.com

We are always looking to expand. Please email us whether you may

want to work with us to expand your product portfolio in your market.

THAILAND

Epunion international enterprise .Co., Ltd. 78/9 Moo 5, Takam, Bangpakong, Chachoengsao, 24130 Thailand.Tel +66 (0) 38 554 324 Fax +66 (0) 38 554 325

CHINA

Epunion (Shanghai) Enterprise Co., Ltd. 7/F Building 1, 818 Road Shenchang, Shanghai, PRC 200335 China.Tel +86 138 1781 3488.